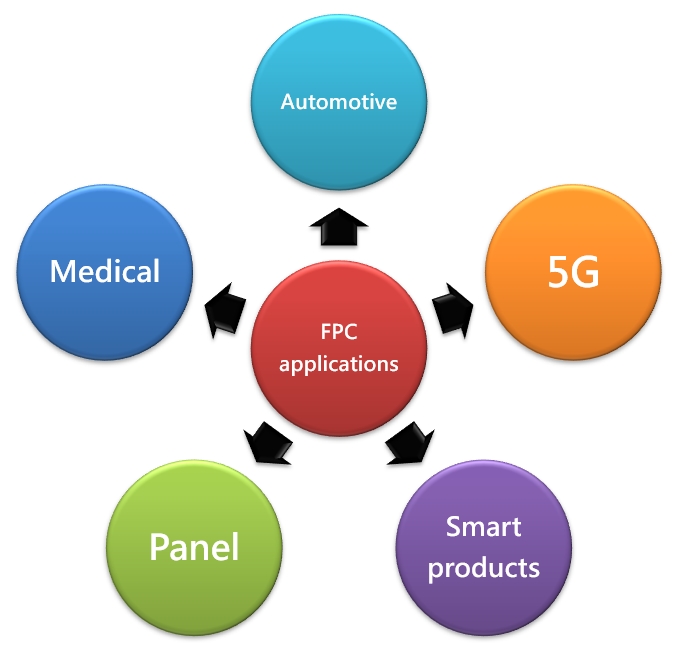

Technology and Process

Flexible Printed Circuit ; FPC

Light weight, thin, flexibility, high adaptability in style design

| Development trend | Applications | Characteristics |

|---|---|---|

| Old generation(Year of 2000) | Cameras, printers, electronic products | Simple circuit structure |

| Next generation(2001~2020) | Medical, panel, smart products, automotive | Complicated circuit design |

| New generation(after 2020) | 5G、AI | Low transmission loss, low dielectric |

- Core technologies(Single-sided board, Double-sided board, Multi-layered board)

- Process Capability(Front-end process, Back-end process )

- Applications(Medical treatment, Panel Smart products, 5G)

Core Technologies

Single-sided

1.Basic structure

2.Simple parts assembly

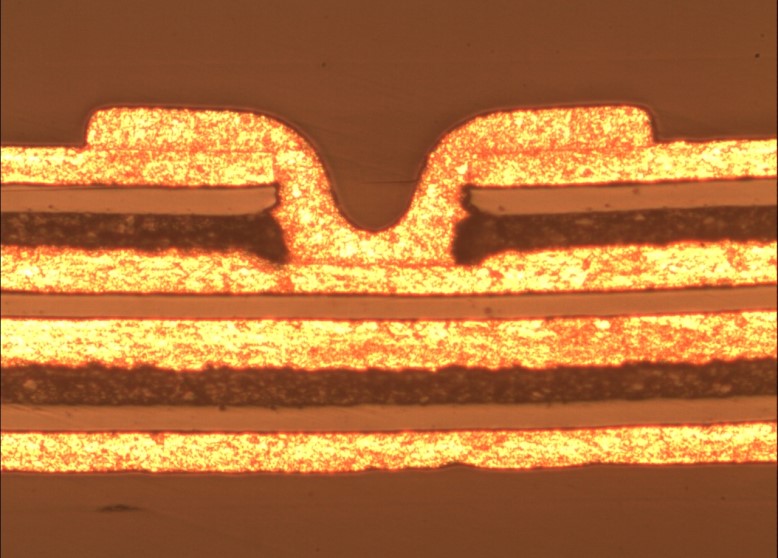

Double-sided

1.Two-layered structure

2.Wiring can be changed

3.Multi-part installation

Multi-layered

1.Over 3 layers

2.Complicated design style

3.Wide functional applications

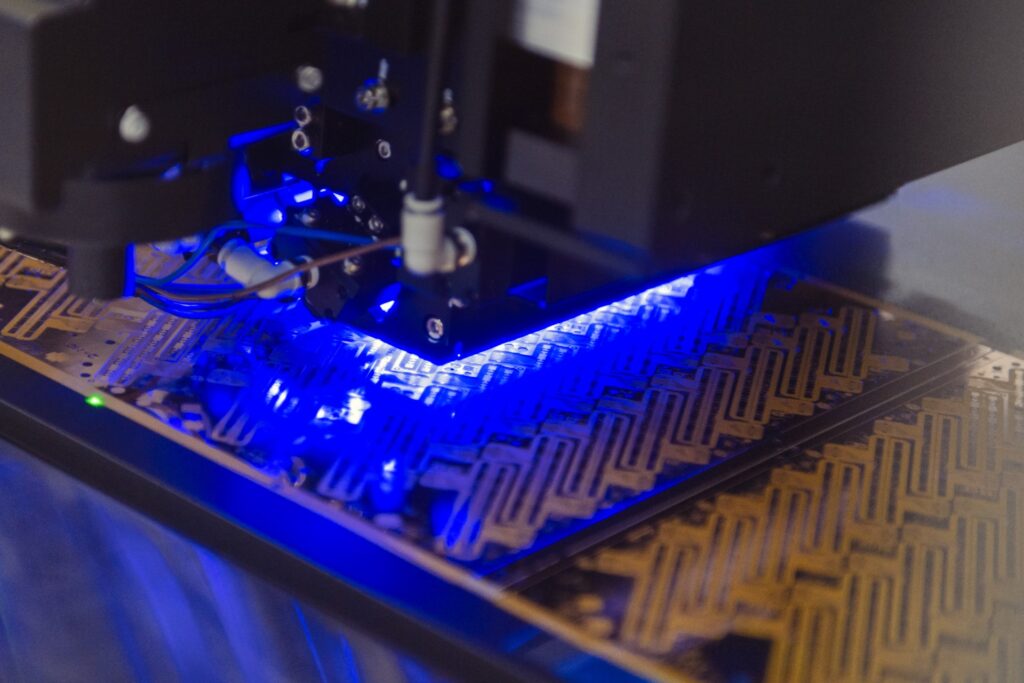

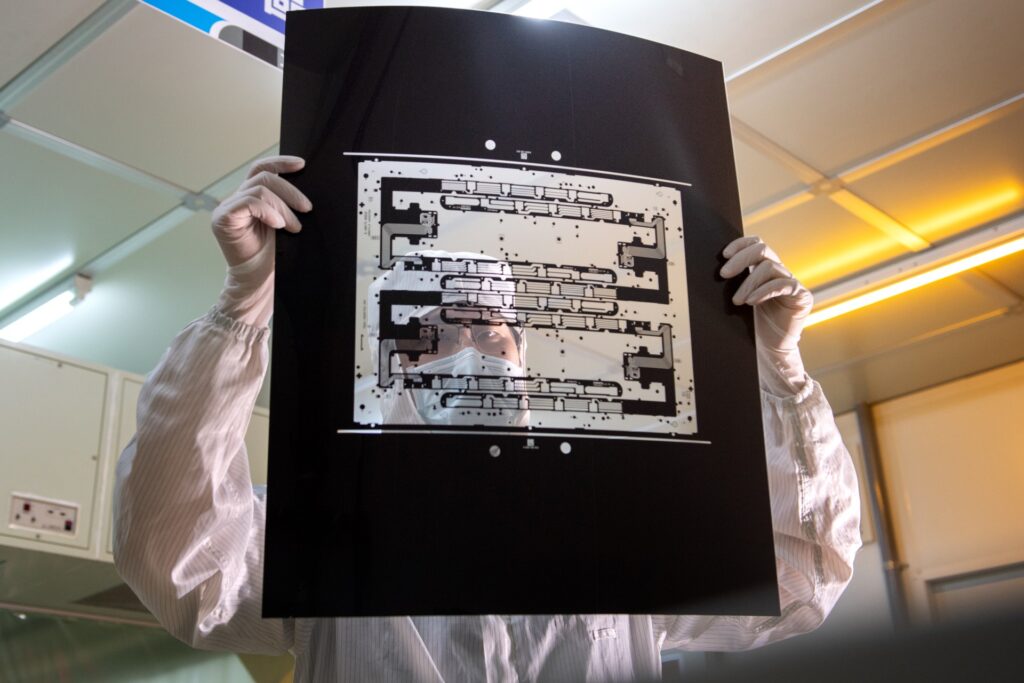

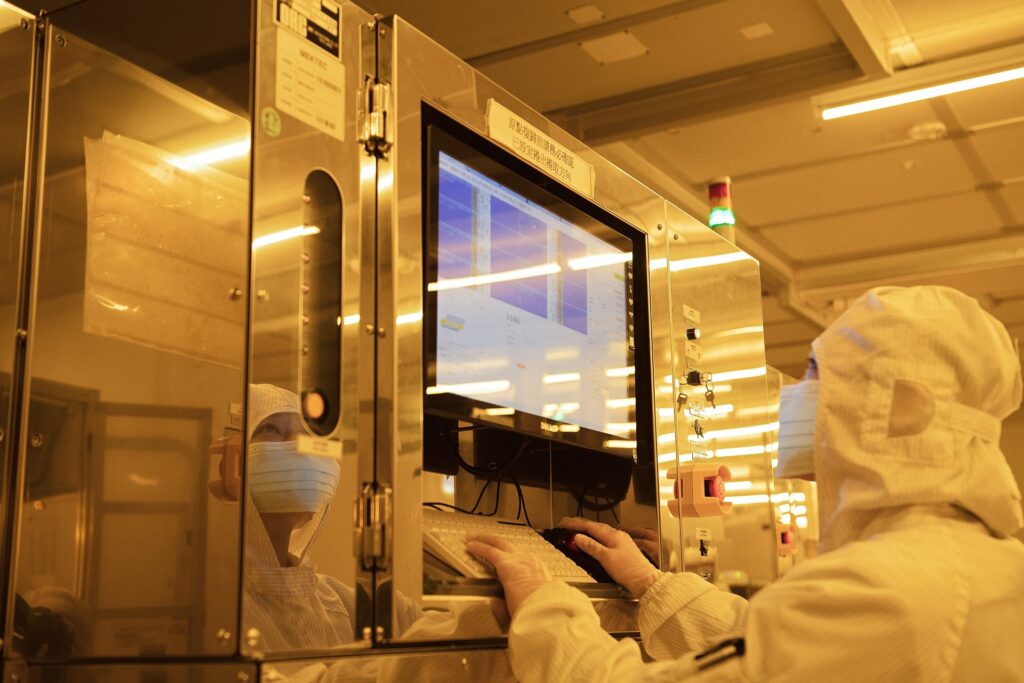

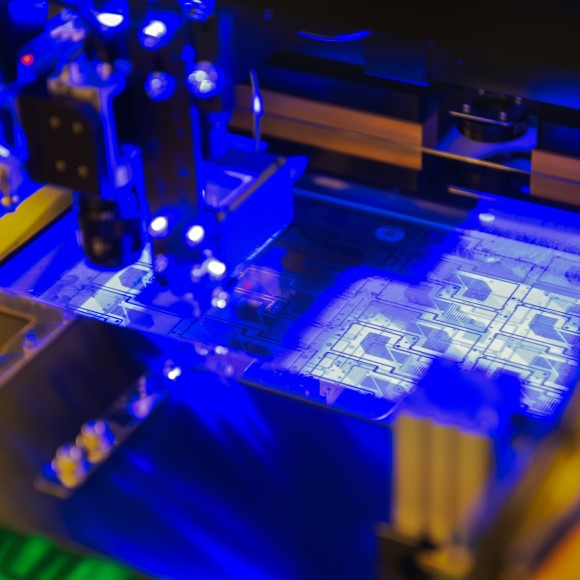

Process Capability

| Process stage | Production process | Process description |

|---|---|---|

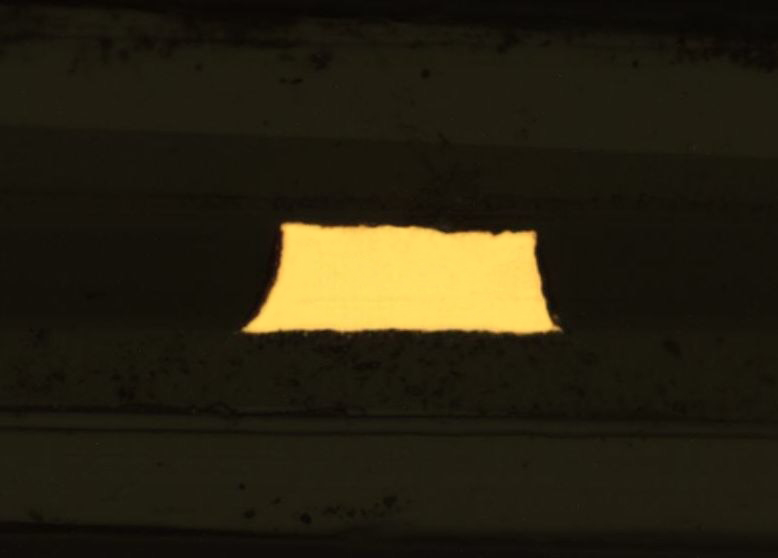

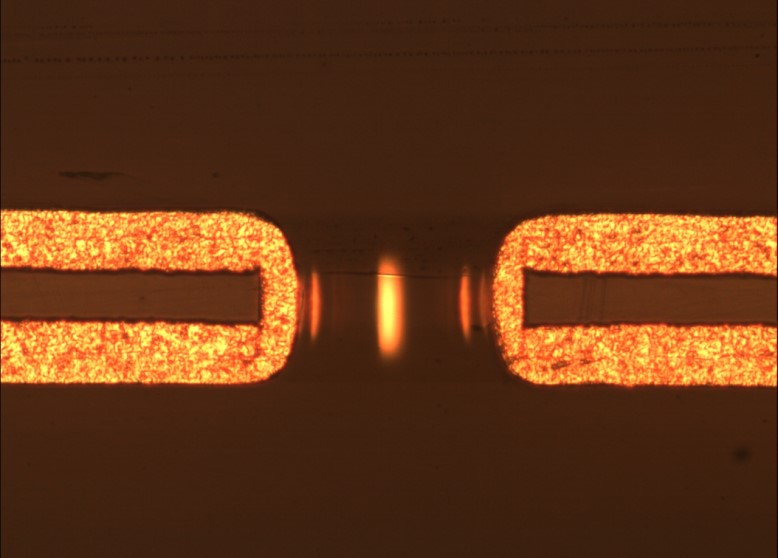

| Front-end process | NC→ Copper Plating→ Circuits Forming→ Lamination→ Solder Mask→ Surface treatment | 1. Hole and circuit forming 2. Surface protection treatment |

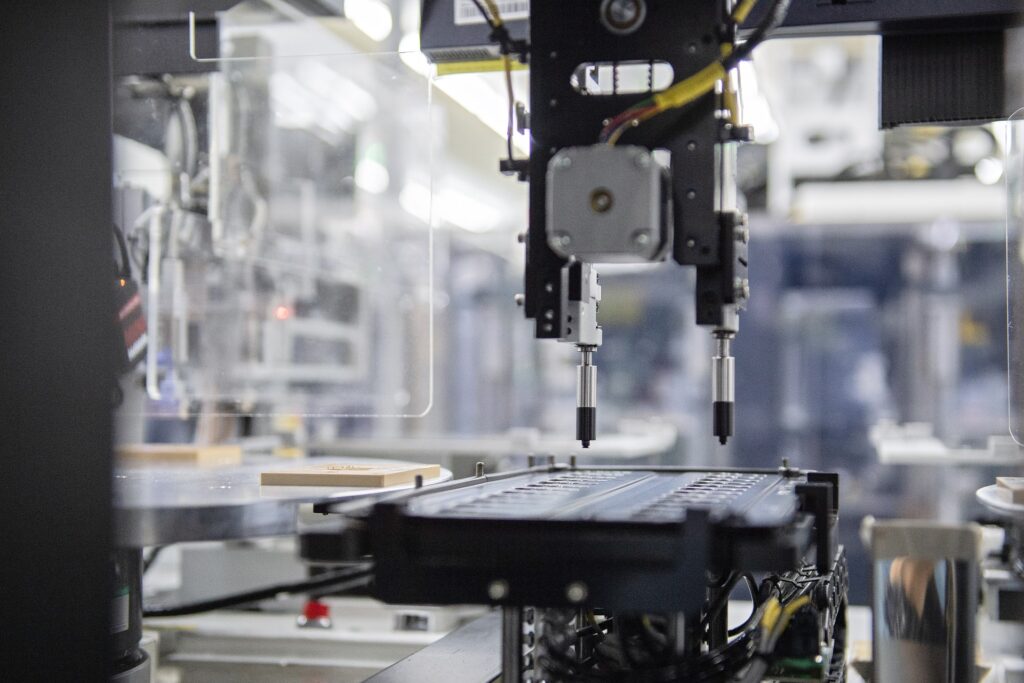

| Back-end process | Stiffening Lamination→ EC measurement→ appearance shaping→ installation | 1. Installing customer-related parts 2. Quality confirmation before shipment |

Applications